Burton, Braswell, Middlebrooks Laboratory

Large-scale Laboratory for Structures & Infrastructure

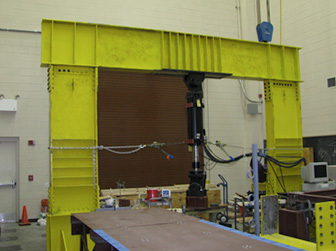

The large-scale structures laboratory at UCF was completed in 2001 in Engineering Building II. It is designed for testing research-related large-scale structural components and systems, infrastructure systems, materials, and performing teaching labs for undergraduate classes.

Facility

- 1600 square feet testing area, 2400 square feet total area.

- 50 ft by 25 ft strong floor in a high-bay area.

- Steel reaction frame.

- Reconfigurable reinforced concrete reactor blocks

- 20-ton overhead crane.

- 3 ft by 3 ft tie-down pattern in the strong floor.

- 100 kips tie-down capacity per point.

Equipment

The laboratory has several hydraulic systems for actuation as well as numerous other pieces of equipment for small-scale tests, data acquisition, and sensing.

- Two 110-kip, +/- 10 in. MTS servo-controlled hydraulic actuators

- Four 100-ton hydraulic jacks

- 200-kip Instron/Satec Universal Loading Machine

- Multi-channel NI-SCXI data acquisition systems

- High shear mixer

- Various transducers and sensors

- Different types of PZT and capacitive, wired, and wireless accelerometers

- Different types of resistive and vibrating wire, high speed, and slow speed strain gages

- Tiltmeters

- Displacement transducers

- A number of other sensors, including sound, pressure, current, and audio/visual, and weather